Top stories

More news

ESG & Sustainability

#Sona2026: President announces crisis committee to tackle SA's water challenges

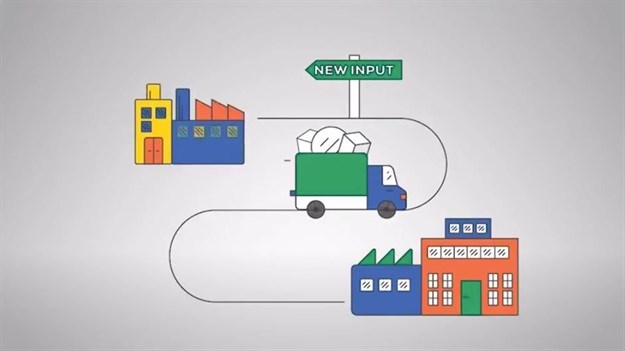

The linear production model where raw materials are converted into products which are replaced by newer products and disposed of after use, is becoming unsustainable. The world is realising that natural resources are finite and running out, or becoming economically unfeasible to extract. Businesses are also reporting that virgin raw materials are becoming more expensive or that they are driven to find solutions because of government regulations that restrict the use and disposal of certain materials.

GreenCape provides free support to business to ensure sustainable and resource efficient growth. We’re seeing that businesses and sectors that are able to anticipate and plan for scarcities and uncertainty by constantly innovating have a better chance of thriving. What has worked in the past will not work tomorrow; a fact demonstrated by the recent drought in Cape Town, which forced businesses to reassess how they use and manage their water resources.

There is a lot of work going into finding more circular approaches to production, which allow the reintegration of used materials back into the economy through recovery, recycling and reuse. The Western Cape Industrial Symbiosis Programme (WISP) is one such example. Circular economy activities like WISP, which is funded by the City of Cape Town, have a wider economic impact as they can spawn new industries like the recycling industry. This in turn boosts the economy and jobs are created which can increase the participation rate of the poor and previously disenfranchised.

WISP and other cleaner production programmes treat one business’s waste as a resource that can be used by another business. Through these programmes, which are often free and funded by government, businesses with a ‘waste’ are matched with ones that can use that 'waste', resulting in a range of benefits for both businesses, from the creation of new income streams, landfill cost savings, to greenhouse gas reductions and better green credentials.

Through WISP's business matching work, more than 33,000 tonnes of material destined for landfill has been diverted back into the economy for reuse since 2013. This means a reduction in demand for virgin materials of the same amount. Businesses that have joined to be matched with other businesses have collectively saved roughly R24m in avoided landfill and costs. New businesses that have been created through matches include solvent recyclers, pallet refurbishers, builders’ rubble processing, textiles recycling, and waste to energy activities.

Breaking with convention has historically allowed us to innovate and advance as a society. With scarcer and more expensive resources, the businesses that use new tools and sustainable materials are the ones that will thrive into the future. The great news is that in South Africa, circular economy programmes like WISP and other provincial industrial symbiosis programmes provide free support to help businesses do just that.