Considering our customer, their products, and the environment

Since all of us in the value chain are responsible for the afterlife of packaging, it is easier to start with the design of the product.

Sustainable packaging starts with the design

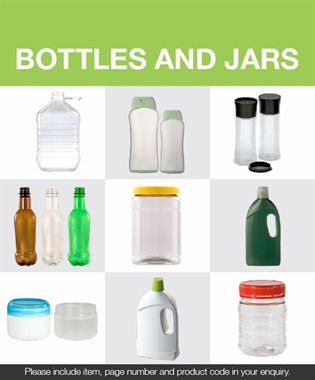

We have designed and developed more than 150 generic products that are fit for purpose.

Our expert Mpact Plastics Innovation and Design teams are able to engage and guide our customers through the generic design to remain within the parameters of ‘designing for recyclability’ in order to achieve an optimal recycling rate. This in turn, assists the brands to also move towards full extended producer responsibility (EPR) compliance.

Customers benefit from generic design

The environmental cost associated with producing multiple moulds is naturally eliminated. A converter can also offer the generic item to a range of brands, allowing them to contribute to larger volumes and lower carbon footprint through more streamlined production processes.

Also, due to economies of scale, generic packaging is more cost-effective to produce as production costs are minimised by fewer mould and material changes in the converter’s factory.

Generic products also prevent stock shortages, have shorter production lead times and improve cash flow due to more frequent, smaller order volumes.

- From idea to shelf: How Mpact brings FMCG packaging to life02 Jul 14:46

- Purposeful packaging for modern life17 Apr 11:23

- Outstanding results for inaugural separation-at-source recycling project28 Mar 12:24

- Unlocking superior packaging with ISBM: Smarter, sustainable solutions12 Mar 11:45

- Committed to bring you smarter, sustainable solutions07 Feb 11:13