Top stories

More news

Marketing & Media

Ads are coming to AI. Does that really have to be such a bad thing?

It's there in our lives already, from the moment we wake up and as we prepare for the day, our commute to work, at work and back home, we could observe at least a handful instances where IoT makes life easier for us.

The Internet of things has opened for us humans a digital world abundant of opportunities, that will further transform the way we learn, interact with each other, with devices, machines and other physical things around us, do business and frankly, the way we will live tomorrow.

The now imperative Internet ubiquity was long predicted, or at least with the first Coke machine on the Internet in 1982 at the Carnegie Mellon University (CMU SCS)1. Another retrospect is the IPv4 depletion that was anticipated in the late 1980s, when we knew 4.3 billion addresses wouldn't suffice the maelstrom of myriad connected devices that is to come. So we came with the IPv6 to support 340 undecillion addresses or simply 340 trillion trillion trillion possible IP addresses.

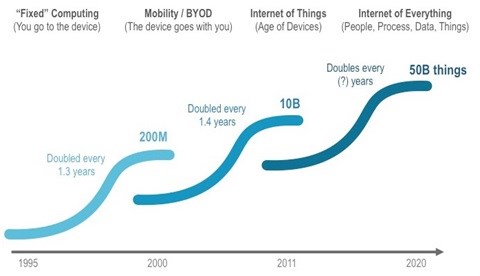

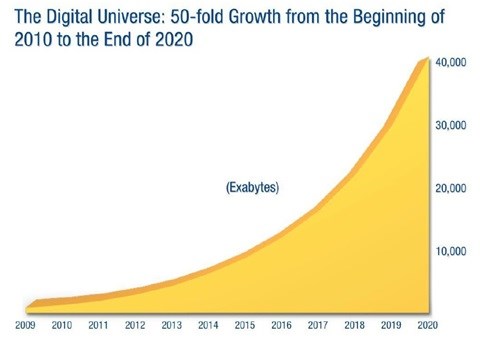

With 16 billion and more IoT devices in 2014, we have moved past the era of solitary, standalone devices (Kerbango)2 to the everything-connected digital universe and 2020 expects to welcome at least 50 billion connected things.

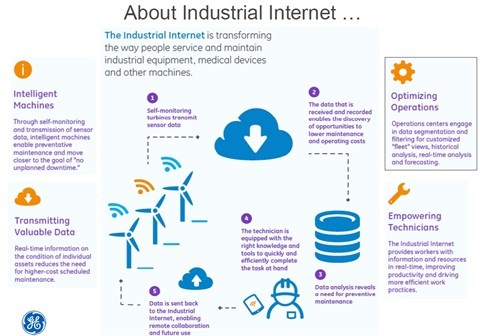

What's then when 75 billion devices (Morgan Stanley, 2013)3 get online? What does it mean for businesses? How about 'Industrial Internet' adding US$ 10-15 trillion (GE Reports, 2013)4 to the global GDP?

Is it all about getting countless unconnected devices online? And how does all that money come about?

With more people and physical objects connected to the Internet, and they start talking to each other brings colossal amounts of data that will be processed and analysed in real-time. From the bulk of data that flows continuously from the connected devices, businesses can use predictive analytics to better understand behavioural patterns, human needs like never before.

Predictive analysis allows each decision to be refined further and for subsequent decisions. Patterns will be recognised, adjustments will be made and performance will be improved, learning and 'thinking' from data collected across multiple points, people and devices. Issues will be diagnosed with more accuracy, reported quickly as they happen.

A looped model that will improve with experience, enabling us to make real-time predictions from identified patterns. A single sensor collecting data at one-second intervals will generate 31.5 million data points a year (Intel-WindRiver)5. But the value lies not just in one sensor's datapoints - but rather the collective intelligence gleaned for thousands (indeed millions) of sensors working together.

The key is the value that we derive out of the billions of devices connected to the Internet. By consuming the information streamed from each device, to use that information to spin insight and derive wisdom of the bigger picture. You translate the wisdom from the connected devices and various processes involved in your businesses, to better understand things and people to better serve your customers after knowing from their needs.

The IoT devices we have in place now is a powerful lesson in capturing data to create actionable intelligence that creates new capabilities and opens up new, prolific levels of productivity. As we move to the years ahead, IoT will generate even greater value, near real-time decision-making and unprecedented economic opportunity.

Recent research confirms manufacturing has been immensely important to the prosperity of nations, with over 70% of the income variations of 128 nations explained by differences in manufactured product export data alone (WEF, 2012)6. For the manufacturing sector, IoT is in fact the third7 industrial revolution.

Manufacturers worldwide are using IoT to transform and disrupt their manufacturing processes. The German government initiated the Industry 4.0 to promote its industry, harness the potential of IoT and Big Data to uncover the colossal opportunities ahead. Several process improvements that IoT can impact for manufacturing, utilities and aviation include automation, factory visibility, power management, proactive maintenance, connected supply chain, etc.

Real-time data-driven decision engines for the factory, which connects with logistic providers, other component manufacturers and their clients, a system that is capable to synchronise all the areas in the supply chain, providing full visibility to all of those involved. A floor where machines are capable to predict failures, run maintenance processes autonomously with nil input from unreliable monitoring by maintenance personnel, where logistics is self-organised when unexpected production changes such as material shortages and bottlenecks happen is the future of manufacturing with IoT.

"Industry 1.0 was the invention of mechanical help, Industry 2.0 was mass production, pioneered by Henry Ford, Industry 3.0 brought electronics and control systems to the shop floor, and Industry 4.0 is peer-to-peer communication between products, systems and machines." - Stefan Ferber8, Director for business development of the IoT at Bosch Software Innovations

In 2004, WalMart introduced RFID to its supply chain teaming with its top 100 suppliers initially. By 2008, they brought in over 15,000 of their suppliers and had their manual orders reduced by 10-15%. Furthermore, the data that WalMart sends from its RFID enabled stores to suppliers to measure the execution and impact of promotions and boost sales.

The ability to track products in the supply chain will improve inventory management while decreasing working capital and logistics costs. IoT while delivering this can add more information such as temperature, geographic location and transport routes as the products traverse the supply chain.

The IoT and real-time data analysis can surpass the Bullwhip effect that is inherent with forecast driven distribution channels. Demand variations at each stage of supply chains calls for some amount of safety as minor deviations in demand gets amplified up the lane. Connected devices that contribute to the intelligent, decision-making network will bring real-time sensitivity and a true pull supply chain for the movement of raw material or the finished product is reflected immediately. This translates to zero inventory storage costs and lost sales and thereby enormous savings for retailers and vendors.

The implementations can:

• Predict delivery delays

• Identify bottlenecks in delivery across multiple stagesRetail

Sales losses on account to shelves that go empty are estimated at 3.9% of sales worldwide9. IoT can help retailers cut losses, track inventory and sales in real-time.

The information from sensors, video footages can give access to specific stages of the buyers' journey as shoppers move through stores- how much time shoppers linger at a particular display, the products they sieved through before making the purchase, etc. By extracting the context, retailers can persona the shoppers and refine their experience further.

For many industries, energy is mostly the second largest operating cost; it is also critical for every person on the planet. IoT can bring reduced costs, better management and availability. In healthcare, the ability to analyse multiple sources of data brings the potential to drive better health outcomes. Health care and insurance providers can iterate health protocols over a population; reduce waste, error rates and lawsuits.

In automotive, predictive models can enable scenario projections and likely outcomes. For instance, if you have three different routes to your destination, with the traffic volume estimate and the estimated increase in volume for each route, your car can decide on the a) safest, b) quickest or c) cheapest route. Urban efficiency over the challenges cities face today- resource scarcity, traffic, pollution, crime and other problems will be transitioned towards smarter, efficient and sustainable places to live. New opportunities for public sector and government to improve public services and homeland security, there would be practically nothing that would be away from the impact of IoT.

As we move past the days, with every new connected device, new dimension of data, the predictive power goes up to address the human needs and wants more precisely. It will open real-time insights for businesses to be able to strategise on changing consumer demands faster.

We can see the day sooner where IoT, predictive analytics and big data will impact our lives unprecedentedly, the decisions we make and the way we will live.

References:

This article originally was published in Ayruz Insights