Top stories

More news

Marketing & Media

Ads are coming to AI. Does that really have to be such a bad thing?

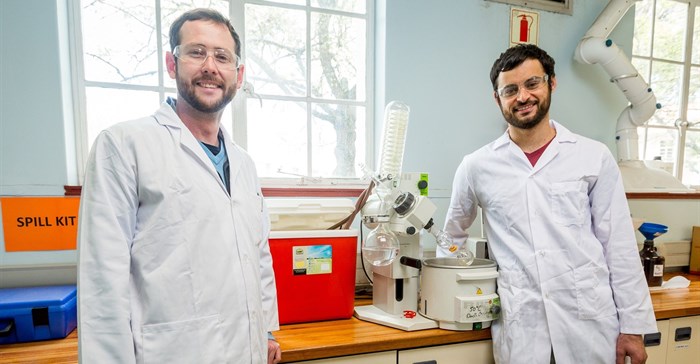

Four months ago they started to conduct trials in the medicinal and organic chemistry laboratory in the De Beers Building in response to a challenge put out by their head of department, Professor Peter Mallon, to develop ways of saving water.

They first identified the largest consumers of water and then developed a system – called a Closed Cold-Water Recycling System (CCWRS) – to be used with various water thirsty lab equipment.

The closed system consists of a cooler box, a garden hose and laboratory silicone piping, as well as a garden fountain pump of 80l/h. The basic principle is that the water is cooled down with ice and then recycled in a closed system, whereas previously perfectly potable tap water would have gone down the drain.

The major water-user identified was the lab’s rotary evaporators, which used over 100l of water per day when running directly from the tap. The evaporator’s condenser is now connected to the closed system and not to a tap, and only uses about five litres of ice water per day.

“All three of our rotary evaporators have been running on this setup for over three months, without failures of any kind even though running eight hours a day, Monday to Friday,” Jonathan explains.

They also found that this method of using ice cold water allowed the solvent to condense far quicker, and that it is also far more effective in condensing low boiling solvents.

Another significant water user is the vacuum suction filtration process, which consumes significant quantities of water in a very short space of time. Instead of each student making use of their own water suction filtration setup in their fume hoods, the lab now has one setup with a Buchi pump which uses no water at all.

“This method of filtration was recently applied in the undergraduate laboratories, where the amount of water saved thus far has been massive. In addition, this method has the advantage of being significantly more efficient – resulting in a much faster and drier filtration step that allows students to continue to the next step more quickly,” the group explains.

Not all initiatives were technical. By simply placing smaller plastic buckets in the large wash basins, they significantly reduced the amount of water used to wash glassware. Now one bucket filled with hot water is usually sufficient for washing two students’ glassware a day.

Professor Willem van Otterlo and Dr Margaret Blackie, the research group leaders for the laboratory, say they hope this initiative will motivate other research laboratories to look for innovative ways of saving water.