Agility, mobility and connection

According to Knowles, cloud and mobile computing, social connection and collaboration technologies that provide agility, mobility and connection will dominate the future of making things for years to come; those not already making use of these technologies are falling behind.

"Fuelled by these technologies in this new future of making things, industries are learning from each other like never before. Now creating a building is often like building a product," explained Knowles.

He used California-based ConXtech as an example of a company that's innovating in the construction sector by "developing connections, methods and products and leveraging automated manufacturing technologies to build faster, better, safer and more sustainably". Knowles compared the erection process using ConXtech technology to an open-air factory where the structure is assembled rather than built.

Optimisation in the designing-making-using cycle

In order to take advantage of the inter-connectivity now available across projects, and to optimise the design and use phases of the product or project, Knowles says "it's essential to go beyond simply optimising the design, we have to optimise how the product is built, as well as the systems that interconnect with it".

"As the link between designing and making gets closer and closer, the feedback loop gets even tighter and it becomes possible to respond to feedback even more quickly."

Sensors that provide real-time, comprehensive feedback can be embedded in places and into things providing vital information that can be incorporated into future designs and processes, explained Knowles.

In 2008 in Seattle, 4000 airline commuters were stranded at the airport during the festive season when a de-icing company ran out of de-icing fluid making it unsafe to fly the aircraft. After reassessing its process, the company added sensors to all its instrumentation, aggregated the information using Autodesk's Fusion Direct software, and now have critical data that is valuable to everyone involved in the entire process - the airline, the de-icing truck operators, as well as the US Environmental Protection Agency. "This is the kind of value the internet of things is really all about," said Knowles.

Transformative for startups too

"While how things are designed and made may be changing, so will the way we work. Anyone, anywhere, on any device will be able to contribute to the project in real time. The bottom line is barriers to productivity are disappearing. This new way of working, this embracing of an era isn't preserved just for large businesses; the future of making will apply to anyone and can be just as transformative for small companies and startups as the big accomplished companies."

London-based gaming startup Sensible Objects created Beasts of Balance, initially known as Fabulous Beasts, a game of strategy and balance that integrates tabletop gaming with digital gaming, using Autodesk's Fusion 360 in various stages of the design process. Players build a tower of animals on their tabletop which helps them evolve in the digital world. The game uses innovative technology that the company developed, including RFID to recognise the pieces, load sensors to sense whether the tower is standing, and Bluetooth to connect to the player’s tablet.

Generative design

Generative design, explained Knowles, uses algorithms to synthesise geometry - all it needs are goals and constraints as input. "This approach allows computers to go off and explore an entire solution space and come back with ideas that we, by ourselves, could never have imagined."

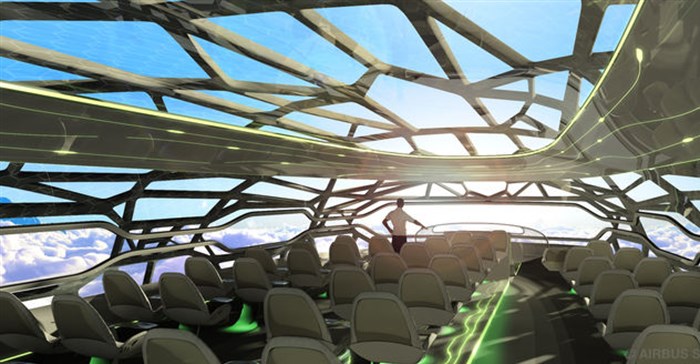

Autodesk has engaged in some generative design work, in partnership with Airbus, to make the aircraft manufacturer's concept plane for 2050 a reality.

Starting with the partition that divides the cabin and supports the jump seats, the algorithm was given performance goals and constraints. It returned options in the tens of thousands that fully met the goals, explained Knowles. Through a collaborative back and forth between the computer and human design team, an optimal design was chosen. The bionic partition weighs much less and is stronger than the original. Each partition has the potential to save 25kg in weight. Airbus, said Knowles, estimate that this will save half a million metric tonnes of CO2 each year. The new partition is currently being tested for flight readiness.

"The present is rapidly changing and the future is almost upon us," concluded Knowles. "Autodesk has been guiding you through a period of technological disruption for well over 30 years now and no company is better positioned or equipped to exploit the opportunities of innovation today."

For more info on Autodesk University Extension South Africa (AUx), go to www.auextension.co.za.