Light-printable and rewritable paper is here

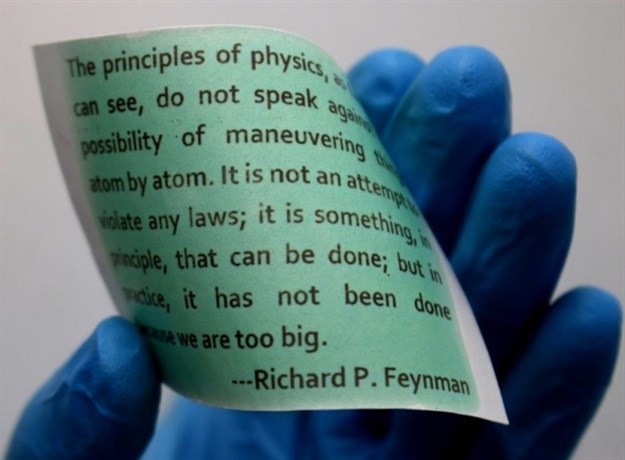

The nanoparticle coating changes colour when ultraviolet (UV) light shines on it and can be reversed when the coating is heated to 120 degrees Celsius. The team of researchers from China and the US say this allows for the paper to be reused up to 80 times, making it cost-effective and environmentally friendly compared to ink-based printing.

The light-printable paper is practical and perfect for when printed information is needed only for a short time. It can be used in newspapers, magazines, posters, and product life indicators, amongst others. The printing lasts at least five days before it slowly begins fading over time. However, the fading process can speed up when exposed to heat.

“The greatest significance of our work is the development of a new class of solid-state photo-reversible colour-switching system to produce an ink-free and light-printable paper that has the same feel and appearance as conventional paper, but can be easily printed and erased repeatedly without the need for additional ink,” Yadong Yin, professor of chemistry at the University of California, Riverside told Phys.org.

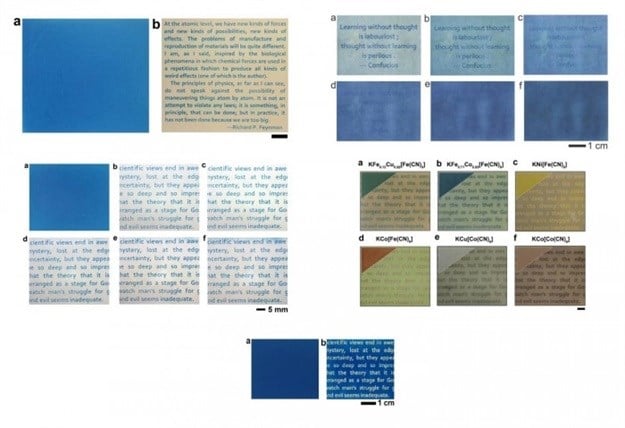

Two types of nanoparticles are combined to create the coating: Prussian blue, a blue pigment used in paints that turns colourless when it gains electrons, and titanium dioxide (TiO2), which is a photocatalytic material that speeds up chemical reactions in response to UV light. A mixture of the two substances creates a solid blue coating. With some UV light, the TiO2 particles release electrons, which turn the Prussian blue pigment colourless. Essentially, the method prints the blank parts of the page.

Since the coating can also be applied on normal paper, the researchers expect the technology to be affordable enough once made on a commercial scale. This invention will have a direct effect on deforestation and the waste of inkjet cartridges.

Source: Design Indaba

Design Indaba inspires and empowers people to create a better future through design and creativity. We are an online publication (www.designindaba.com) with an annual festival and social impact Do Tank.

Go to: www.designindaba.com