The technology used to produce renewable energy has advanced by leaps and bounds over the last 10 years, providing a greater output at lower costs. Energy storage, on the other hand, has been a persistent bugbear. LiGE believes it has the answer.

LiGE's Eco-MC2 is a hydraulic energy storage system that is able to store renewable energy. We chatted to co-founder Magriet Leaper about the design of the technology, how it works in comparison to regular battery storage, and how it could benefit the business sector.

"The team has been at the design and construction of an efficient, clean, no-batteries energy storage system for the last three years. There have been various iterations and changes over that time and we now have a very efficient unit," says Leaper.

Inconsistent power supply

The idea stemmed from a visit with a friend in 2012 who was upset that the inconsistent power supply was ruining his exotic flower beds as it affected his sprinkler system. This triggered a brainstorm session in which solar panels came out tops - the only problem was how to store the energy for when the sun went down.

"The idea to store energy using hydraulics was born that day," says Leaper. The first prototype, she explains, was made out of old car parts, old generators, clutches, motors and the end result was that it worked. "We all clapped happily it stored energy. However, we realised very quickly that this unit would be extremely large, so we went back to the drawing board."

Months later, compressed air energy storage was decided on as the ideal medium. But how does it work, and how has design-based innovation been incorporated into the making of Eco MC2?

"The various sub-structures in the design, such as the electronics for the control monitoring and reporting software, are custom built. The composite pressure vessels are specially made to our requirements of 'zero' fatigue factor and explosion proof, etc. There are lots of safety features built into the system to ensure a safe and tamper-free system. After all, this is a power plant. We monitor pressure, heat, vibration, flow rates, current, voltage, and various security measures. The enclosure is sealed, so is tamper-free. When tampered with, the system will shut down and de-pressurise. Only one of LiGE’s technicians will be able to open the enclosure with a signal from head office and only LiGE’s technicians will be able to maintain and commission the systems," explains Leaper.

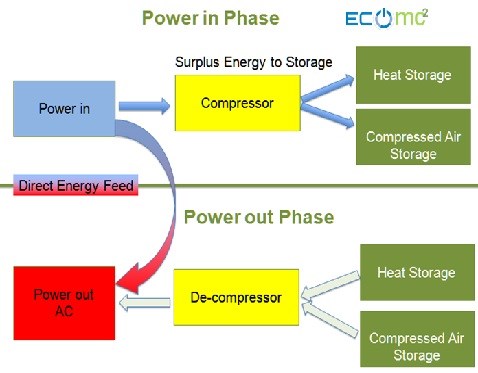

"The operation uses power derived from solar, though not exclusively, to drive a hydraulic motor which drives a compressor. That compressed air is stored in air tanks. This reverse operation drives an alternator which supplies the electrical power to the factory, building, etc. The roundtrip efficiency is better than 90%.

"The unit is primarily designed as an off-grid solution for renewable energy systems but also fits the application of an uninterruptible power supply-type environment, providing a greater storage period," Leaper explains.

Better than batteries

Battery storage is inadequate as it has a limited life-span of stored energy. At the end of their life-span, batteries are toxic and require special treatment for disposal. Most conventional batteries contain heavy metals and components manufactured with scarce resources.

Eco-MC2, on the other hand, has no toxic emissions, and a zero-carbon footprint, according to its creators. In addition, the life-span of the storage solution is about 30 years, something which batteries, in their current form, cannot achieve.

"Our technology is centred around compressed air energy storage systems (CAES). Under normal circumstances CAES would be in underground caverns. We, however, redesigned this to work above ground in specialised pressure vessels which allows us to place this storage system anywhere in the world!" says Leaper.

How will Eco-MC2 benefit the business sector? Apart from saving on electricty costs, the system's zero carbon emissions will be a benefit once the Carbon Tax is implemented in 2017.

For more on LiGE's Eco-MC2, go to

www.lige.co.za.